After reading this article you will able to understand all aspects of CNC programming. Here is a complete guide on CNC programming, CNC programmer career, etc.

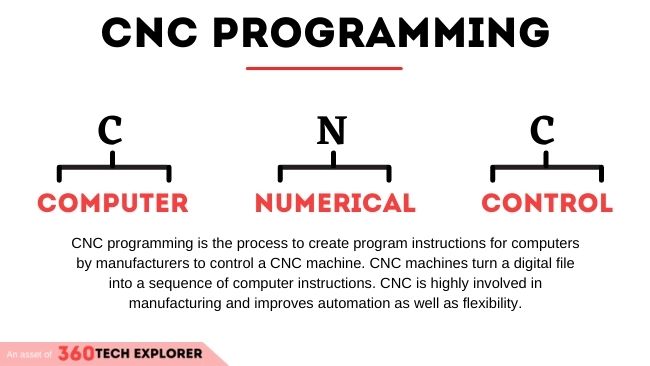

What is CNC Programming?

CNC stands for computer numerical control. CNC programming is the process to create program instructions for computers by manufacturers to control a CNC machine. CNC machines turn a digital file into a sequence of computer instructions. CNC is highly involved in manufacturing and improves automation as well as flexibility.

G-Code vs M-Code

In CNC programming there is two type of code:

G-Code

What is G-Code

G-code is a software programming language used to control a CNC machine. And, even with complex CNC machining, G-code is written in a straightforward, logical way.

A “G” is followed by a number, which is a command to change geometry. For instance, “G00” is a command for rapid movement. It moves the tool to part geometry at the maximum rate and is generally used to move the tool and part from near to far or vice versa.

Examples of G-Code

G00

The above code rapid move to a specific coordinate position

G01

The above code Linear feed move

G02/G03

The above code Clockwise/counterclockwise feed move

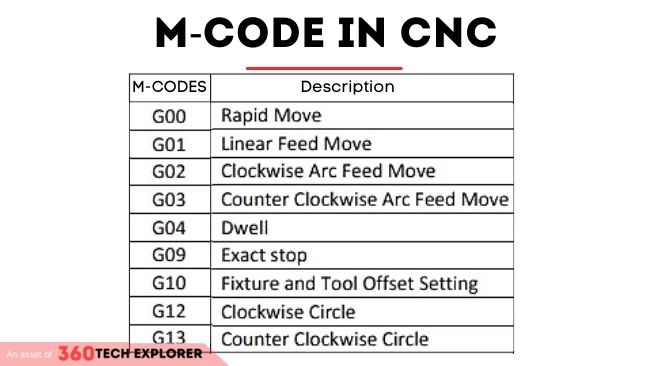

M-Code

What is M-Code

M-code controls miscellaneous functions, and typically these can be thought of as non-geometry machine functions. Examples include spindle rotation start and stop, coolant on and off, pallet change, etc. Some of these functions may vary by the specific machine.

Examples of M-Code

M00

The above code stop whatever function the program is currently doing

M03

The above code rotate spindle clockwise

M08/M09

The above code flood coolant on/off

Best CAD software that supports CNC Machining

- Fusion 360

- Rhino3D

- SketchList3D

- AutoCAD

- SolidWorks

CNC Programmer Career

CNC machines are used around the world. This isn’t an area-specific job, so there is a lot of flexibility when it comes to location. Whether you want to take your skills to the west coast, east coast, or even another country, there will most likely be opportunities available to you.

According to Todd, technical schools like Universal Technical Institute are doing a great job of providing a pipeline of students who are ready to go into the industry. Many of these students go on to gain real-world experience working as machinists, which can open the door to advancing to a programmer role.

Stats: There are currently 1,531 jobs are open. (According to Indeed.com)

How to Become CNC Programmer?

In order to become a CNC programmer, an appropriate academic degree lasting 4-5 years is usually required. Degrees in the fields of Computer Science, and engineering are suitable options.

In order to get to know the profession of the CNC programmer, it is highly recommended to do an internship in advance in order to be clear about the tasks of the profession before embarking on the career.

What Does CNC Programmer Do?

CNC programmers are responsible for the proper operation and programming of CNC machines using CNC programming that allows sending instructions to motorized tools. How do you become a CNC programmer and what are the day-to-day responsibilities?

Skills required

CNC programmers have expertise in the field of computer science – especially coding, and have know-how in the fields of mechanical and systems engineering. Technical skills include knowledge of CAD, manufacturing software, and in the fields of mathematics and physics.

Soft skills include a structured and responsible way of working and logical thinking, especially when working on CNC coding.

What must a CNC programmer be able to do?

- Strong knowledge of G – Codes and M – codes for CNC machines

- Know-how of Computer-Aided Design software – AutoCAD or Solidworks is popular CAD software

- Experience with Computer-Aided Manufacturing (CAM) software – e.g. Powermill, Fusion 360

- Good understanding of blueprint readings and plans

- Experts in industry and government safety standards

- Knowledge of setting drills, mills, and lathes to ensure 100 percent accuracy

- Strong mathematics ability – including trigonometry and geometry

- Keen sense of analysis and logical thinking

Salary

Starting Salary $60,000

Average Salary $75,000

Senior Salary $100,000

*This based on data.

1 thought on “What is CNC Programming: Complete Guide”

You have covered the detailed information about the CNC programming and CNC operator’s job role and the skills as well. I got such valuable insights. Thank you for such a valuable write-up. Keep sharing such valuable writing pieces.